A drill is one of the best tools around the house because of its multiple uses. You can use it, for example, when changing scenery, putting up a shelf, building a cabinet … However, there are several different drills for different tasks. For the average DIYer, a set of high-speed steel twist drill bits will be sufficient. For sophisticated jobs, other specific bits can be used. The right choice depends on the utility, price, quality, Subsequently, we will help you understand forests so that you can choose the right drill for your project.

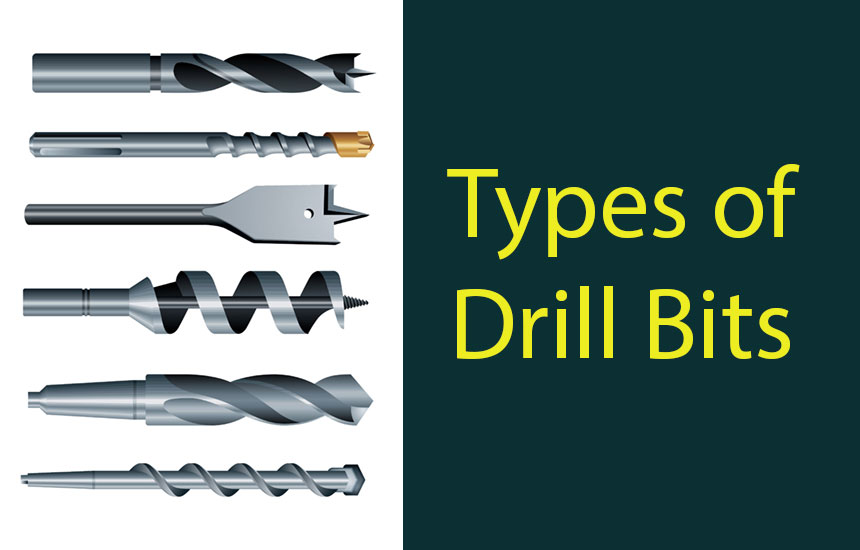

14 Different Types of Drill Bits:

1- Twist drill bits

Twist drills are the most common forage tools used by the DIY enthusiast with a manual or electric drill. They can be used on different materials such as light metal, plastic, metal, wood, ceramic, or even masonry and similar materials. Twist bits are useful for various repair, maintenance, and construction jobs. Twist bits have a general-purpose rotary drill. For home use, the twist drill is the most common type of drill.

Twist bits are made of carbon steel (ground bits for wood drilling). They are sensitive, brittle, and less flexible than HSS bits.

2- Screwdriver bits

Screwdriver bits can be used with many materials. It is useful and ideal for construction projects and mechanical works. Screwdriver bits are used with hand drills and impact screwdrivers, depending on the type. This drill bit is designed to fit a rechargeable screwdriver. These bits have a hexagonal shank. They are able to pierce pants pilots.

3- Masonry Drill Bits

Masonry jaws are used to drill in several materials such as wood, brick, and stone… Masonry drills are used in an electric drill or a hand splint. Masonry bits can be used with an impact drill. When drilling hard materials, use a slow rotating speed to avoid overheating the tip. Masonry jaws have masonry bits 300-400mm long for drilling masonry walls.

4- Peak Drill Bits

Drill bits are used for drilling wood or plastics only. The wood or dowel bit has a central point, and two raised spurs. The advanced bit drill bit cuts wood easily by an electric drill leaving a clean hole. They are ideal for piercing clean, parallel pants. Its sizes vary between 3 to 10 mm. sharpening is delicate and must be done manually.

5- Pilot bullet point Drill Bits

The pilot bullet point has a central point, and two spurs drills can be used for wood, metal, and plastics. It has a precise bit (from 1.5 to 13 mm), which allows cutting a clean hole with a little damage by crossing the part’s back. The sharpening not satisfactory.

6- Milling Drill Bits

Milling is used in an electric or manual drill. Drill bits are designed for the use of flexible materials (wood and plastics). Cutters are having handles adjusted for manual use. Sharpening is difficult. End mill with undercut drill. It drills the clearance hole. Milling is adaptable for an electric drill or some routers. There are different drill bits for different sizes of release pants. Sharpening is difficult given the shape of the spur tips.

7- Tile Drill Bits

Tile bit allows you to drill ceramic and glass. It has a ground tungsten carbide tip. It can be used with a hand drill and better in an electric drill. Sharpening is difficult since the tungsten carbide is hard and the cutting edge is curved.

8- Flat wood Drill Bits

The drill bit is used only with an electric drill. The central point locates the drill. Drill bits are suitable for piercing large pants and for making a flat bottom hole.

9- Bell Saw

A hole saw is used to cut large fixed diameter pants in wood or plastic. Their depth is 18 mm. For sharpening, it could be done either with a thin triangular file or for a regular saw.

10- Versatile Tungsten Micro Drill Bits

These drills are very versatile. They can be used either hammer or rotary. Versatile bits have a diamond ground tungsten tip that allows it to drill into wood, plastic, ceramics, metal, and masonry. To drill masonry, you must use the rotary mode as the hammer mode can damage the coated point.

Versatile bits has several advantages, such as their versatility, multiple uses, and their diamond tip. However, it is not the right decision for the masonry, and he gets dull with the constant use of the hammer.

11- HSS Titanium Drill Bits

The drill bit is covered in titanium, which allows it to reduce overheating. Besides, extend the bit’s life (up to six times longer than other comparable drills). The steel drill bit makes it fast and able to drill through wood, metal, and plastics. HSS titanium nitride bits require less maintenance than other types. HSS Titanium Nitride Tips is characterized, therefore, by its durability, robustness, ability to reduce overheating, and it is excellent for metal, wood, and plastic.

Its disadvantages are that it can lose its titanium coating when sharpened, and it is more expensive than other types.

12- Cobalt HSS bits

Cobalt drill bits can drill steel, cast steel, stainless steel, cast iron, bronze, other high strength steels. Cobalt HSS bits are constructed of precision ground alloy steel and solid cobalt. They are resistant to high temperatures and abrasion. Its advantages are manifold. It is capable of drilling through steel and is resistant to wear temperature and abrasion. The only disadvantage of Cobalt HSS bits is that it is not suitable for wood.

13- Reduced Shank HSS Bits

Drill bits can pierce pants larger than the width of the chuck. Having a larger hole diameter and a reduced shank that allows it to fit the drill chuck.

Reduced Shank HSS Bits are ideal for drilling wood, metal, and plastics. It is ideal for standard drills. Its only disadvantage is that it only fits large pants.

14- HSS Rivet Bits

HSS Rivet Bits are designed to drill small pants for rivet insertion. They have fluted sides to increase the longevity of the bit. The hole depth of HSS Rivet Bits does not exceed one and a quarter times the diameter of the hole, and the drilled hole should be larger than the rivet for expansion and fatigue reduction.

The advantages of HSS Rivet Bits are manifold. It has a specialized rivet bit, fluted sides, and it is durable.

The disadvantages of HSS Rivet Bits are as follows. It is unable to pierce only small pants, and they are only suitable for rivets.

Frequently Asked Questions

Question 1: Cobalt Vs. Titanium Drill Bits: which is better?

Answer: The two cobalt and titanium drills have things in common. They can both be used for hard surfaces and resist heat when drilling. The differences between the two drills are as follows:

Cobalt drill bits are uncoated and are constructed from an alloy of steel and cobalt. Cobalt drills are able to be sharpened without damage, which allows them to retain their protections. Titanium drills are less robust than cobalt ones. Titanium drills are constructed from titanium nitride, or titanium carbonitride.

Question 2: what is a carbide drill bit?

Answer: A carbide drill bit is enhanced with the cobalt drill bit. They are mainly used for drilling the hardest materials. They are able to deflect heat, maintain sharpness longer, and operate very fast.

Question 3: What are the characteristics of metal drills?

Answer: Metal drills are diverse and specific. It can withstand the heat and power of metals. The most common metal drills are:

TWIST OR HIGH-SPEED STEEL

High-speed steel or HSS bits are able to work on different metals from aluminum or hard cast iron. It can handle the highest speeds from electric drills.

COBALT AND TITANIUM COATED

Standard HSS bits are capable of performing a wide variety of common jobs.

Cobalt bits are made from a mixture of steel and cobalt; on the other hand, titanium bits are made from steel bits and coated with titanium.

Both drills can be used for various types of metals. Titanium drill bits are more durable, and cobalt is able to drill through the toughest materials.

Conclusion:

We present above the main types of drills. They are very different, specific, and each has its characteristics and uses. For example, titanium coated drills are strong, cobalt drills are stronger, and carbide drills are the strongest. Wood and metal bits are not the only bits on the market, but they are most commonly used since they can handle many tasks. The types of forests are many and different.

Therefore, you should choose the drill bit according to your requirement, price, and quality. We hope you find this guide helpful and provide you with valuable information about different types of Drill Bits You Need to Know.